Injection Molding Seminar Classes – Molding Simulation

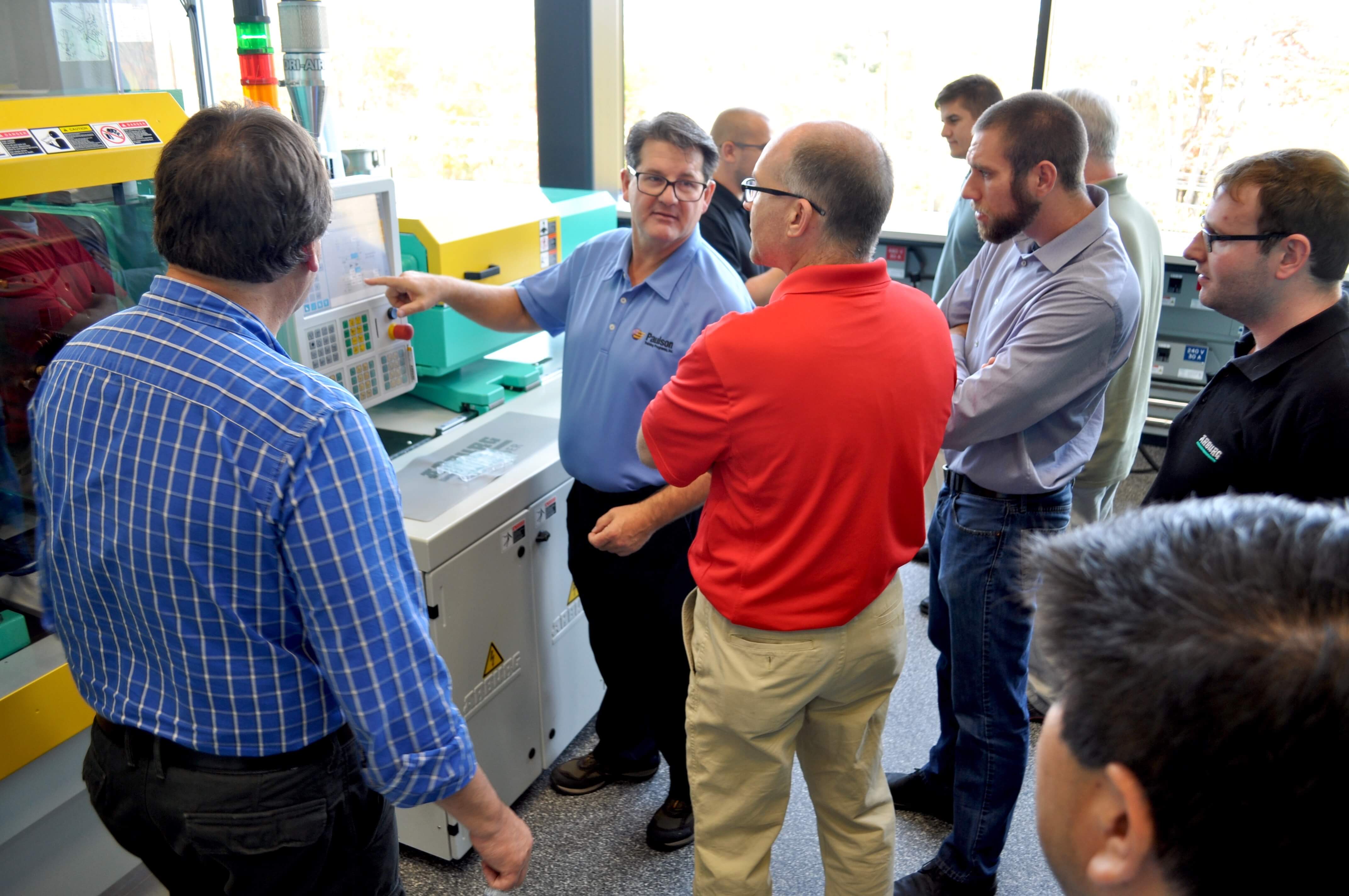

There are a number of injection molding seminars out there to choose from and most advertise at least some “hands-on” machine time (including Paulson ProMolder™ seminars). There is no substitute for getting in front of the molding machine and having the opportunity to actually try out what you have learned during class. You can’t become a good injection molder without this hands-on experience.

There is also a middle ground between the classroom and the real machine. This is where injection molding simulation comes in. Note that we’re talking about simulating the entire machine, not just mold filling simulation. The aviation industry has relied on simulator technology since World War II. Many other industries make use of simulators. Among them nuclear power plant operation, piloting tanker ships, oil refinery operations, and many more. The military is perhaps the single largest adopter of simulation technology. That makes sense. Simulation is particularly appropriate in situations that involve:

- Potential danger when first learning a new skill set

- Where using the actual machine is expensive

- Where the ability to try out scenarios that could possibly be dangerous exist

- When there is the potential for damage to the equipment that would be expensive to repair

- Where time savings in learning machine operation is very valuable

In the injection molding industry, all 5 of the above criteria are met. Injection molding machines are potentially dangerous to someone new to the industry. Machine time is expensive. Few, if any companies can afford an injection molding machine dedicated to training. With the high pressures and temperatures involved in the molding process, there are limits to how far you can push the real machine. Injection molding simulators have no such limits. A damaged machine or mold can be very expensive both in terms of the actual repair and in production time lost. Using injection molding simulation also lets your employees learn faster.

You can easily run 10 simulated machine cycles for every 1 you could run on a real machine.

But again, there is no substitute for actual machine time. However, it doesn’t have to be all your “at-the-machine” training. The airlines and military routinely give their pilots flight currency check rides in simulators.

One example of how simulation can speed up each cycle is that temperature changes are reflected immediately on the molding machine simulator. It could take 10 – 15 minutes to see the full effects of a barrel temperature change on an actual machine.

Paulson’s SimTech™ injection molding machine simulator is a key part of our ProMolder™ seminars. We also include hands-on machine time.

But just to illustrate how effective the use of SimTech is in the ProMolder 1 and 2 seminars, on our post seminar evaluation sheets

When asked “What did you like most about this seminar?” the #1 response is always “the simulator”

Our students like it because they are getting more training bang for their buck. And their employers like it for the same reason. So when you’re evaluating what injection molding seminar will be right for you, give ProMolder a serious look. The SimTech simulator will get you a lot of “virtual” machine time prior to getting in front of the actual machine.